The information communicated within this announcement is deemed to constitute inside information as stipulated under the Market Abuse Regulations (EU) No. 596/2014 which is part of UK law by virtue of the European Union (withdrawal) Act 2018. Upon the publication of this announcement, this inside information is now considered to be in the public domain.

12 November 2024

Neometals Ltd

("Neometals" or "the Company")

Positive Results from ELi™ Pilot Trial

Highlights:

· ELiTM has achieved the objectives of the pilot stage of its electrolysis technology readiness;

· The crystallisation trial produced high purity lithium hydroxide monohydrate crystals and will produce further samples for market evaluation;

· The electrolysis trial data supports the expected power consumption and membrane life assumptions, and hydrodynamic testing confirmed the equipment can be applied to commercial-scale operation;

· The final stages of the Pilot trial involved a 1,000-hour electrolysis test of a lithium chloride solution (South American brine source), purified with ELi™ technology and crystallisation of the lithium hydroxide product;

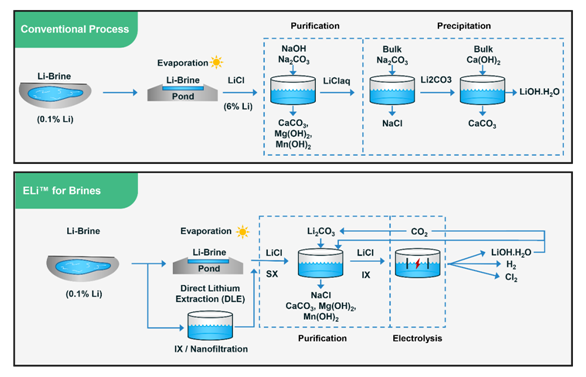

· The ELi™ Process potentially delivers users a step-change reduction in operating costs to convert lithium chloride brines to lithium hydroxide (or carbonate) with electrolysis, virtually eliminating bulk reagents.

Sustainable process technology developer, Neometals Ltd (ASX: NMT & AIM: NMT) ("Neometals" or "the Company"), is pleased to announce the results of the final electrolysis and crystallisation stages of the ELi™ Process ("ELi™") Pilot trial ("Trial"). ELi™ is owned by Reed Advanced Materials Pty Ltd ("RAM"), a 70:30 incorporated joint venture between Neometals Ltd and Mineral Resources Ltd.

The technology uses electricity to convert lithium chloride solutions into lithium hydroxide in a conventional chlor-alkali cell, replacing the need for large volumes of bulk chemical reagents required in the industry-standard, chemical precipitation process. ELi™ has the potential to deliver users a step-change in operating costs[1] versus industry standard chemical precipitation.

RAM completed a long-duration 1,000-hour electrolysis membrane durability test utilising a lithium chloride solution produced in the successful 2023 'purification' trial on brine sourced from South America[2]. The Trial tested the performance of the electrolysis cell membrane over a duration five times longer than historic tests and the results support current estimates of two major variable operating costs (power consumption and membrane life) and successfully produced lithium hydroxide monohydrate ("LHM") of very high purity.

Table 1 - LHM Sample Analysis

|

Element[3] |

LiOH % |

CO32-% |

Na ppm |

Ca ppm |

K ppm |

Fe ppm |

SO4 ppm |

|

Target Spec |

>56.5 |

<0.4 |

20 |

10 |

10 |

10 |

100 |

|

Sample 1 |

56.6 |

ND |

1.8 |

6.0 |

5.6 |

8.2 |

2.4 |

|

Sample 2 |

56.9 |

ND |

3.6 |

9.7 |

5.1 |

8.6 |

1.5 |

Additionally, further samples are being produced for qualitative evaluation.

These results are significant as they confirm or exceed historic results achieved from processing synthetic brine solutions (from commercial lithium chloride crystals) at continuous laboratory scale on less-pure eluate from natural brine, at a pilot scale and over a longer duration. The increased confidence in major operating cost inputs supports the potential operating cost advantage of the ELi™ process in the conversion of lithium chloride brines and is a major milestone in the commercialisation of the technology under a low-capex, low-risk technology licensing business model to generate future royalty income. RAM holds 19 granted patents in the principal lithium producing jurisdictions and has a further 14 pending national phase patents at various stages of prosecution globally.

Figure 1 - Schematic comparison flowsheet of the conventional lithium hydroxide from brines vs the patented ELi™ process.

ELi™ Electrolysis Pilot Trial Results

The current efficiency for the Trial averaged approximately 74% and trended upwards during the course of testing, consistent with historical electrolysis results on synthetic brine solutions. The current efficiency measures the actual catholyte produced as a percentage of the maximum possible production and, pleasingly, the results support the electricity consumption assumption in the 2023 Engineering Cost Study[4].

The Trial membrane was physically inspected and chemically analysed following completion of testing, to determine the extent of any deterioration which may have arisen during the tests. The membrane was observed to be in excellent condition and no significant build-up of elements was identified in the membrane destructive digestion test. A shorter 40-hour duration test examined the hydrodynamic performance and polarisation characteristics of a full-height commercial electrolysis cell. This test successfully confirmed the flowsheet can be applied to commercial-scale electrolysis cells. This outcome gives confidence this is an effective means of producing a suitable solution for production of battery grade lithium hydroxide monohydrate ("LHM").

The lithium hydroxide catholyte from electrolysis was processed in the crystallisation trial to produce LHM final product. Sample splits of the product were sent for analysis in separate laboratories, in South Africa and Australia. The Australian analytical laboratory is considered to have greater reliability in determinations of very low concentration impurities (in low ppm and in ppb-level concentration of impurity elements), so the Australian laboratory results for impurities are reported. Some carbonation of the sample sent to the Australian laboratory was observed in the analysis, but this has been traced to the sample not having been packed in an inert atmosphere and aging in transit to Australia. Lithium hydroxide readily carbonates by absorbing the carbon dioxide in air but contact with air does not change the content of other impurities. The sample sent to the South African laboratory was not exposed to ambient carbon dioxide and analysis did not detect any carbonation in the sample. The South African laboratory lithium hydroxide and carbonate results are considered reliable and are reported.

The combined analysis results meet the target specifications listed in Table 1. Sample product is being produced for further evaluation by both RAM and the owner of the South American brine source.

Forward Plan

ELiTM has satisfied the objectives of the pilot stage of its electrolysis technology readiness. RAM has prepared an information memorandum and data room to commence a formal industrial partner selection process, with the aim of advancing the technology through industrial validation, in demonstration plant trials.

RAM continues to evaluate third-party brine samples and to advance discussions with chlor-alkali plant manufacturers in relation to preferred vendor relationships.

Authorised on behalf of Neometals by Christopher Reed, Managing Director.

- ENDS -

For more information, please contact:

|

Neometals Ltd |

|

|

Chris Reed, Managing Director & Chief Executive Officer |

+61 8 9322 1182 |

|

Chris Kelsall, CFO & Company Secretary |

+61 8 9322 1182 |

|

Cavendish Capital Markets Ltd - NOMAD & Broker |

|

|

Neil McDonald |

+44 (0)131 220 9771 |

|

Peter Lynch |

+44 (0)131 220 9772 |

|

Adam Rae |

+44 (0)131 220 9778 |

|

|

|

About Neometals

Neometals facilitates sustainable critical material supply chains and reduces the environmental burden of traditional mining in the global transition to a circular economy.

The Company is commercialising a portfolio of sustainable processing solutions that recycle and recover critical materials from high-value waste streams.

· Neometals' core focus is its patented, Lithium-ion Battery ("LiB") Recycling technology (50% NMT), being commercialised in a 50:50 incorporated JV (Primobius GmbH) with 150-year-old German plant builder, SMS group GmbH. Primobius is supplying Mercedes-Benz a 2,500tpa recycling plant and operates its own LiB Disposal Service in Germany. Primobius' first 21,000tpa commercial plant will be offered to Stelco under an existing technology licence for North America.

Neometals is developing two advanced battery materials technologies for commercialisation under low-risk, low-capex technology licensing business models:

· Lithium Chemicals (70% NMT) - Patented ELi™ electrolysis process, co-owned 30% by Mineral Resources Ltd, to produce battery quality lithium hydroxide from brine and/or hard-rock feedstocks at lowest quartile operating costs. Successfully completed pilot scale test work and planning further development with industrialisation partners under a technology licensing business model; and

· Vanadium Recovery (100% NMT) - Patent pending hydrometallurgical process to produce high-purity vanadium pentoxide from steelmaking by-product ("Slag") at lowest-quartile operating cost and carbon footprint. Planning to exploit under a technology licensing business model. Project financing process for first commercial plant in progress.

For further information, visit: www.neometals.com.au.

[1] For full details refer to Neometals ASX announcement dated 26th April 2023 and titled "Lithium - Exceptional Engineering Cost Study Results"

[2] For full details refer to Neometals ASX announcement dated 10th November 2023 and titled "Successful ELiTM Purification Pilot Trial"

[3] LiOH and CO32- analysis reported by a South African laboratory and the other elements reported by an Australian laboratory

[4] For full details refer to Neometals ASX announcement dated 26th April 2023 and titled "Lithium - Exceptional Engineering Cost Study Results"

RNS may use your IP address to confirm compliance with the terms and conditions, to analyse how you engage with the information contained in this communication, and to share such analysis on an anonymised basis with others as part of our commercial services. For further information about how RNS and the London Stock Exchange use the personal data you provide us, please see our Privacy Policy.