Spanish Mountain Gold Drilling Intersects 103.35 Metres Grading 0.88 g/t Gold With a Higher-Grade Subset of 56.40 Metres of 1.35 g/t Gold

This press release features multimedia. View the full release here: https://www.businesswire.com/news/home/20260203389419/en/

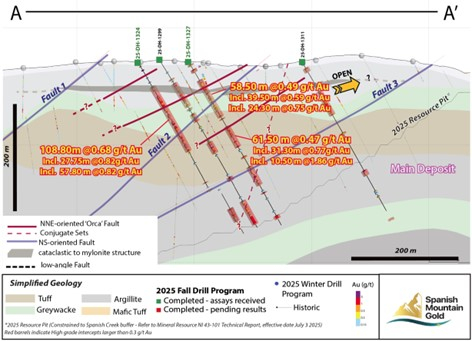

Figure 1: Drill Long Section Through Orca Fault Area (looking northeast); section line A-A’ (see Figure 4)

The company has completed approximately 10,870 metres (“m”), surpassing the original estimate of drilling of 9,000 to 10,000 m of exploration drilling planned under the 2025 Fall Drill Program, now continuing into 2026. Assays and geochemistry are pending receipt from the laboratory and/or reporting from four additional drill holes completed within the Orca Fault target area.

Highlights:

-

25-DH-1324 intersected broad gold mineralization from 69.00 m totaling 108.80 m grading 0.68 g/t gold that include two key intervals:

- 27.75 m of 0.82 g/t gold from 69.00 m including 18.01 m of 1.10 g/t gold; and

- 57.80 m of 0.82 g/t gold from 120.00 m including 3.08 m of 1.42 g/t gold and 2.42 m of 4.10 g/t gold.

-

25-DH-1325 intersected two intervals of gold mineralization including:

- 103.35 m of 0.88 g/t gold from 15.65 m including 56.40 m of 1.35 g/t gold with a high-grade subset of 9.90 m of 3.54 g/t gold; and

- 15.15 m of 0.65 g/t gold from 255.00 m including 1.85 m of 3.28 g/t gold.

-

25-DH-1326 intersected three intervals of gold mineralization including:

- 116.50 m of 0.44 g/t gold from 20.00 m including 83.50 m of 0.51 g/t gold with a high-grade subset of 36.70 m of 0.79 g/t gold;

- 10.00 m of 0.64 g/t gold from 191.00 m including 4.00 m of 1.28 g/t gold; and

- 34.50 m of 0.82 g/t gold from 288.50 m including 18.00 m of 1.31 g/t gold with a high-grade subset of 3.50 m of 3.21 g/t gold.

Key Findings:

- Current exploration drilling assay results continues to intersect significant higher-grade mineralization over 530 m in strike length in the Orca Fault target area (Figure 4) and the continuity can now be traced across multiple parallel, adjacent drill sections over 80 to 190 m.

Main Deposit – Orca Fault area

Four additional drill holes were collared and successfully completed (see Figure 4) in the Orca Fault target area, 25-DH-1324 (Figure 1 and Table 1), 25-DH-1325 (Figure 3 and Table 2), 25-DH-1326 (Figure 2 and Table 3), and 25-DH-1327 (Figure 1, Figure 3, and Table 4). These drill holes continue to confirm and lend confidence to the extent of the Orca Fault target area over 530 m strike length, northwest to southeast, and its geological and structural interpretation within the constraining open pit for the MRE (see

The continued intersection of wide zones of higher-grade gold mineralization, such as in drill hole 25-DH-1325 (Figure 3 and Table 2) reinforces the opportunities for not only enhancing the Orca Fault target understanding but developing favorable structures outward into other areas of the Main deposit while exploring for higher-grade gold mineralization in the near surface, open pit environment, as defined in the recent MRE (see

The analytical results from the lower portion of drill hole 25-DH-1324 (see Figure 1 and Table 1) were released and significantly lengthen the previously published main composite (see

All results to date continue to reinforce that tighter exploration drill spacing is unlocking additional mineral potential in the Main deposit. These exploration drill holes are presented on drill sections (Figure 1, Figure 2, and Figure 3) that shows the alignment of the higher-grade mineralization to the new Orca Fault target. The location of these drill holes is shown on a plan map at the end of the news release (Figure 4).

Table 1: Assay Results for 25-DH-1324

|

Drill hole |

From (m) |

To (m) |

Width (m) |

Gold (g/t) |

Apparent True Thickness |

|

25-DH-1324 |

16.00 |

17.15 |

1.15 |

13.47 |

Note 3) and 4) |

|

|

50.45 |

58.30 |

7.85 |

0.53 |

Note 3) and 4) |

|

Including |

50.45 |

51.80 |

1.35 |

1.17 |

Note 3) |

|

|

69.00 |

177.80 |

108.80 |

0.68 |

Note 3) and 5) |

|

Including |

71.18 |

89.19 |

18.01 |

1.10 |

Note 3) and 4) |

|

Including |

78.00 |

89.19 |

11.19 |

1.16 |

Note 3) and 4) |

|

Including |

69.91 |

97.66 |

27.75 |

0.82 |

Note 3) |

|

Including |

120.00 |

177.80 |

57.80 |

0.82 |

Note 3) and 5) |

|

Including |

122.00 |

125.08 |

3.08 |

1.42 |

Note 3) and 4) |

|

|

131.00 |

133.42 |

2.42 |

4.10 |

Note 3) |

|

|

240.00 |

240.50 |

0.50 |

1.57 |

Note 3) |

Table 2: Assay Results for 25-DH-1325

|

Drill hole |

From (m) |

To (m) |

Width (m) |

Gold (g/t) |

Apparent True Thickness |

|

25-DH-1325 |

15.65 |

119.00 |

103.35 |

0.88 |

Note 3) |

|

Including |

44.00 |

100.40 |

56.40 |

1.35 |

Note 3) |

|

Including |

90.50 |

100.40 |

9.90 |

3.54 |

Note 3) |

|

|

147.48 |

148.70 |

1.22 |

1.12 |

Note 3) |

|

|

255.00 |

270.15 |

15.15 |

0.65 |

Note 3) |

|

Including |

268.30 |

270.15 |

1.85 |

3.28 |

Note 3) |

|

|

288.80 |

290.50 |

1.70 |

1.86 |

Note 3) |

Table 3: Assay Results for 25-DH-1326

|

Drill hole |

From (m) |

To (m) |

Width (m) |

Gold (g/t) |

Apparent True Thickness |

|

25-DH-1326 |

20.00 |

136.50 |

116.50 |

0.44 |

Note 3) |

|

Including |

20.00 |

103.50 |

83.50 |

0.51 |

Note 3) |

|

Including |

64.00 |

100.70 |

36.70 |

0.79 |

Note 3) |

|

Including |

64.00 |

80.00 |

16.00 |

1.32 |

Note 3) |

|

|

155.55 |

165.00 |

9.45 |

0.48 |

Note 3) |

|

|

191.00 |

201.00 |

10.00 |

0.64 |

Note 3) |

|

Including |

192.50 |

196.50 |

4.00 |

1.28 |

Note 3) |

|

|

288.50 |

323.00 |

34.50 |

0.82 |

Note 3) |

|

Including |

303.50 |

321.50 |

18.00 |

1.31 |

Note 3) |

|

Including |

318.00 |

321.50 |

3.50 |

3.21 |

Note 3) |

Table 4: Assay Results for 25-DH-1327

|

Drill hole |

From (m) |

To (m) |

Width (m) |

Gold (g/t) |

Apparent True Thickness |

|

25-DH-1327 |

17.85 |

22.85 |

5.00 |

0.75 |

Note 3) |

|

|

39.50 |

98.00 |

58.50 |

0.49 |

Note 3) |

|

Including |

39.50 |

79.00 |

39.50 |

0.59 |

Note 3) |

|

Including |

50.70 |

75.00 |

24.30 |

0.75 |

Note 3) |

|

Including |

56.54 |

66.53 |

9.99 |

1.21 |

Note 3) |

|

|

132.50 |

194.00 |

61.50 |

0.47 |

Note 3) |

|

Including |

140.20 |

172.50 |

31.30 |

0.77 |

Note 3) |

|

Including |

162.00 |

172.50 |

10.50 |

1.86 |

Note 3) |

|

|

212.00 |

248.00 |

36.00 |

0.55 |

Note 3) |

|

Including |

231.00 |

236.00 |

5.00 |

2.87 |

Note 3) |

|

|

263.00 |

264.00 |

1.00 |

1.43 |

Note 3) |

|

|

308.10 |

314.00 |

5.90 |

1.22 |

Note 3) |

|

Notes for Table 1 to Table 4: |

|

1) Reported intersections are calculated using a 0.15 g/t Au cut-off grade. |

|

2) The complete assay table is available on the Company’s website |

|

3) True thickness of mineralization is unknown as the project is still at the exploration stage |

|

4) Assay composites previously released |

|

5) Re-calculated composite for interval partially released |

The integration of assay results from these four exploration drill holes strengthens the overall continuity for the new Orca Fault target and the association of higher-grade mineralization over a strike length of 530 m, northwest to southeast (see Figure 4). Stronger continuity is also now being developed spanning multiple, parallel, adjacent drill sections ranging in strike length from 80 to 190 m, northeast to southwest, depending on the location along the 530 m strike length (see Figure 2).

Figure 4 illustrates the locations for four drill hole results outlined in this news release and the drill holes currently in the assay lab, or in process of being drilled. Drill collar location coordinates are summarized for the 2025 Fall Drill Program in Table 5 at the end of this news release.

Qualified Person

Abbreviations: metres = m, grams per tonne = g/t, gold = Au, mineral resource estimate = MRE,

Drill Core Processing, Data Verification and Quality Assurance – Quality Control Program (QAQC)

Once received from the drill and processed, all drill core samples were sawn in half, labeled, and bagged. The remaining half of the drill core was securely stored on-site. Numbered security tags were applied to sample shipments to ensure chain of custody compliance. The Company inserts quality control (QC) samples at regular intervals, including blanks and reference materials, for all sample shipments to monitor laboratory performance.

Standards and blanks account for a minimum of 20% of the samples in addition to the laboratory’s internal quality assurance programs. The QAQC program was overseen by the Company’s Qualified Person,

The data verification process involved a multi-step approach to ensure accuracy and integrity. This included a detailed quality control (QC) analysis of the data, which was performed using both internal and external platforms, such as the MxDeposit™ software. These QC checks involved the analysis of certified reference materials (CRMs), blanks, and duplicates to confirm the reliability of the assay results. In addition, a field inspection of the specific drill intervals mentioned in this release has been conducted to directly observe the geological features and verified the nature of the results presented.

Drill core samples were submitted to MSALABS’s analytical facility in

PhotonAssayTM

The PhotonAssayTM method utilizes gamma ray analysis for gold detection using the Chrysos PhotonAssayTM instrument (PA1408X). This non-destructive, fully automated technique offers high accuracy for analyzing ores and pulps. Sample preparation begins with drying and crushing up to 1 kg of material to achieve at least 70% passing through a 2-millimetre (mm) sieve. The sample is then riffle split to obtain a suitable aliquot for 2 testing cycles (MSALABS Method CPA-Au1).

The PhotonAssayTM instrument bombards 400- to 600-gram samples contained in sealed containers with gamma rays. These containers remain sealed throughout the process, preserving the sample for potential further testing. The analysis is performed robotically, with results that integrate into existing laboratory management systems. Each sample is accompanied by a reference disc traceable to a Certified Reference Material (CRM). Both the sample and reference disc undergo gamma ray exposure, with signals detected and analyzed to ensure accurate and reliable results. The method offers a gold detection range from 0.015 parts per million (ppm - lower limit) to 10,000 ppm (upper limit). Quality control includes the use of reference materials and blanks, with all results reviewed by a competent person before reporting.

Multi-Elemental Analysis

For the 2025 drilling campaign

Key Process Steps:

Sample Preparation: Samples are dried and ground to a specific criterion (85% passing 75 microns (μm) for rocks and drill core; 180μm for soils and sediments). A homogeneous 10-gram sample is required. Digestion: Samples undergo sequential digestion with nitric, perchloric, hydrofluoric, and hydrochloric acids, followed by dilution with deionized water.

Analysis: The solution is analyzed via ICP-OES and ICP-MS for multi-element quantification.

Quality Control: The process includes reference materials, blanks, and duplicates, with corrections for spectral interferences and thorough review before final reporting.

About

On Behalf of the Board,

“Peter Mah”

President, Chief Executive Officer and Director

Neither the

FORWARD-LOOKING INFORMATION:

Certain of the statements and information in this press release constitute "forward-looking information". Any statements or information that express or involve discussions with respect to predictions, expectations, beliefs, plans, projections, objectives, assumptions or future events or performance (often, but not always, using words or phrases such as "expects", "anticipates", "believes", "plans", "estimates", "intends", "targets", "goals", "forecasts", "objectives", "potential" or variations thereof or stating that certain actions, events or results "may", "could", "would", "might" or "will" be taken, occur or be achieved, or the negative of any of these terms and similar expressions) are not statements of historical fact and may be considered forward-looking information. The Company's forward-looking information is based on the assumptions, beliefs, expectations and opinions of management as of the date of this press release and include but are not limited to statements with respect to, the potential for adding more higher-grade gold mineralization within the pit or outside the current pit design; and the receipt of further results from additional drilling under the 2025 Fall Drill Program, and the plan to make a construction decision in 2027. Other than as required by applicable securities laws, the Company does not assume any obligation to update forward-looking information if circumstances or management's assumptions, beliefs, expectations or opinions should change, or changes in any other events affecting such statements or information. For the reasons set forth above, investors should not place undue reliance on forward-looking information.

Table 5: Drill Collar Information for Drill Holes

|

Hole ID |

EAST |

NORTH |

ELEV |

AZIMUTH |

DIP |

DEPTH |

COMMENT |

|

25-DH-1334 |

604254 |

5827971 |

1116 |

120 |

-60 |

N/A |

In Progress |

|

25-DH-1333 |

604236 |

5828012 |

1104 |

120 |

-60 |

N/A |

In Progress |

|

25-DH-1332 |

604185 |

5828088 |

1091 |

120 |

-65 |

372 |

Successfully completed per design |

|

25-DH-1331A |

604595 |

5827901 |

1103 |

120 |

-60 |

240 |

Successfully completed per design |

|

25-DH-1331 |

604594 |

5827899 |

1103 |

120 |

-60 |

55 |

Ended early due stuck drill rods |

|

25-DH-1330 |

604332 |

5827990 |

1105 |

120 |

-60 |

351 |

Successfully completed per design |

|

25-DH-1329 |

604467 |

5827962 |

1090 |

120 |

-60 |

255 |

Successfully completed per design |

|

25-DH-1328 |

604278 |

5828018 |

1105 |

120 |

-58 |

402 |

Successfully completed per design |

|

25-DH-1327 |

604411 |

5828026 |

1088 |

120 |

-60 |

327 |

Successfully completed per design |

|

25-DH-1326 |

604327 |

5827963 |

1108 |

120 |

-60 |

351 |

Successfully completed per design |

|

25-DH-1325 |

604385 |

5827966 |

1103 |

120 |

-60 |

309 |

Successfully completed per design |

|

25-DH-1324 |

604343 |

5828053 |

1080 |

120 |

-60 |

276 |

Successfully completed per design |

|

25-DH-1323 |

604286 |

5828046 |

1097 |

120 |

-60 |

338 |

Successfully completed per design |

|

25-DH-1322 |

604279 |

5827995 |

1106 |

120 |

-60 |

231 |

Successfully completed per design |

|

25-DH-1321 |

604350 |

5828016 |

1099 |

120 |

-60 |

348 |

Successfully completed per design |

|

25-DH-1320 |

604561 |

5827809 |

1126 |

120 |

-60 |

57 |

Ended early due to major fault zone |

|

25-DH-1319 |

604404 |

5827992 |

1095 |

120 |

-70 |

198 |

Successfully completed per design |

|

25-DH-1318 |

604445 |

5828098 |

1055 |

120 |

-60 |

243 |

Successfully completed per design |

|

25-DH-1317 |

604186 |

5828166 |

1076 |

120 |

-60 |

282 |

Successfully completed per design |

|

25-DH-1316 |

604514 |

5828073 |

1050 |

120 |

-60 |

177 |

Successfully completed per design |

|

25-DH-1315 |

604231 |

5828163 |

1075 |

120 |

-60 |

282 |

Successfully completed per design |

|

25-DH-1314 |

604160 |

5828218 |

1056 |

120 |

-70 |

270 |

Successfully completed per design |

|

25-DH-1313 |

604566 |

5827908 |

1100 |

120 |

-60 |

204 |

Successfully completed per design |

|

25-DH-1312 |

604538 |

5827921 |

1095 |

120 |

-60 |

205 |

Successfully completed per design |

|

25-DH-1311 |

604590 |

5827935 |

1084 |

120 |

-60 |

330 |

Successfully completed per design |

|

25-DH-1310 |

604592 |

5827961 |

1091 |

120 |

-60 |

211 |

Successfully completed per design |

|

25-DH-1309 |

604592 |

5827958 |

1071 |

120 |

-60 |

237 |

Successfully completed per design |

|

25-DH-1308 |

603280 |

5829250 |

966 |

120 |

-60 |

150 |

Successfully completed per design |

|

25-DH-1307 |

604565 |

5827974 |

1068 |

120 |

-60 |

200 |

Successfully completed per design |

|

25-DH-1306 |

603451 |

5829400 |

927 |

120 |

-60 |

123 |

Successfully completed per design |

|

25-DH-1305 |

603657 |

5829226 |

919 |

120 |

-60 |

126 |

Successfully completed per design |

|

25-DH-1304 |

604536 |

5827986 |

1067 |

120 |

-60 |

225 |

Successfully completed per design |

|

25-DH-1303 |

603960 |

5828754 |

943 |

100 |

-55 |

156 |

Successfully completed per design |

|

25-DH-1302 |

604194 |

5828180 |

1066 |

120 |

-63 |

282 |

Successfully completed per design |

|

25-DH-1301 |

603708 |

5829029 |

929 |

150 |

-55 |

188 |

Successfully completed per design |

|

25-DH-1300 |

604388 |

5828063 |

1085 |

120 |

-60 |

274 |

Successfully completed per design |

|

25-DH-1299 |

604369 |

5828043 |

1093 |

120 |

-60 |

336 |

Successfully completed per design |

|

25-DH-1298 |

604402 |

5828088 |

1074 |

120 |

-59 |

334 |

Successfully completed per design |

|

25-DH-1297 |

604354 |

5828069 |

1084 |

120 |

-59 |

342 |

Successfully completed per design |

|

25-DH-1296 |

604484 |

5828054 |

1061 |

120 |

-50 |

180 |

Successfully completed per design |

|

25-DH-1295 |

604484 |

5828054 |

1061 |

120 |

-60 |

33 |

Ended early due to drill trace spacing |

|

25-DH-1294 |

604345 |

5828120 |

1075 |

120 |

-58 |

351 |

Successfully completed per design |

|

25-DH-1293 |

604284 |

5828149 |

1076 |

120 |

-60 |

453 |

Successfully completed per design |

|

25-DH-1292 |

604223 |

5828189 |

1068 |

120 |

-62 |

270 |

Successfully completed per design |

View source version on businesswire.com: https://www.businesswire.com/news/home/20260203389419/en/

For more information, contact:

(604) 601-3651

info@spanishmountaingold.com

Source: